XSC-CIRCUITS PROFILE

Shenzhen Xu Shenchuang Circuit Technology Co.,Ltd is a leading manufacturer specializing in HDI, rigid-flex, FPC, ceramic substrates, high-frequency, and multi-layer PCBs. With over 300 employees, including 40+ engineers, we operate a fully automated facility with 100+ core machines. Our products serve various industries, including automotive electronics, industrial control, medical, aerospace, and more.

We provide a wide range of PCBs, including 1-36 layer HDI, rigid-flex, ceramic, and high-frequency microwave PCBs, alongside comprehensive PCB and PCBA services. We prioritize quality, innovation, and customer satisfaction through advanced technologies and robust process controls.

At XSC-CIRCUITS, we are committed to delivering exceptional service and fostering long-term, mutually beneficial partnerships, while contributing to global progress and embracing corporate social responsibility.

QUALITY FIRST, SERVICE ABOVE ALL

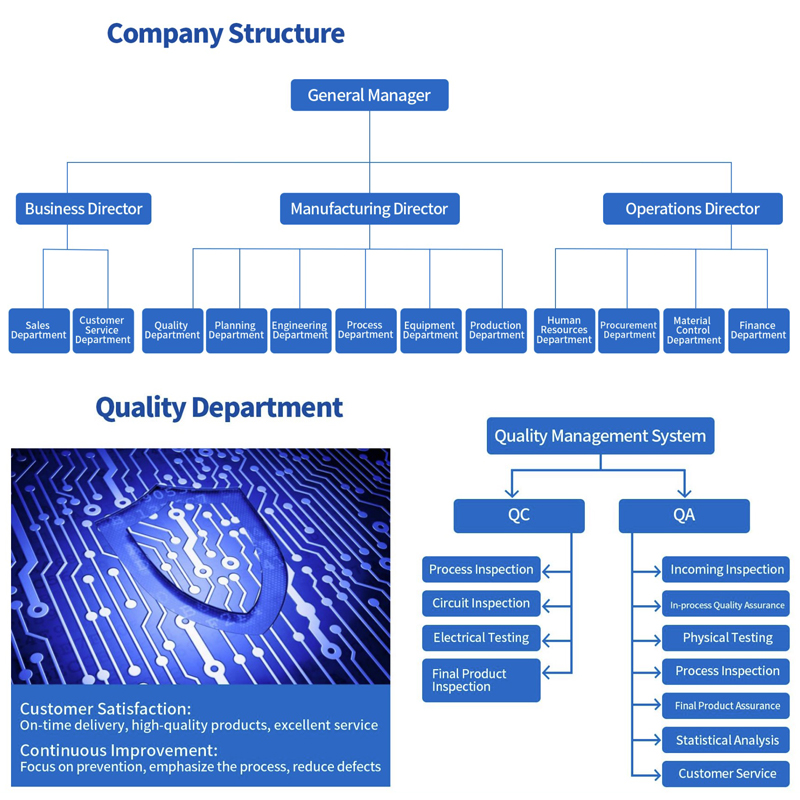

Customer Requirements Identification and Conversion:APQP translates customer requirements into actionable specifications, ensuring relevant departments are trained and requirements are implemented through follow-up.

Supplier Management:The SQE department manages suppliers to ensure a shared sense of responsibility, aiming for mutual benefit and rapid development within the supply chain.

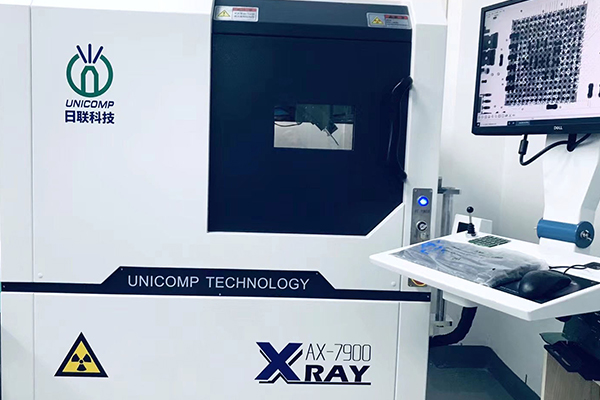

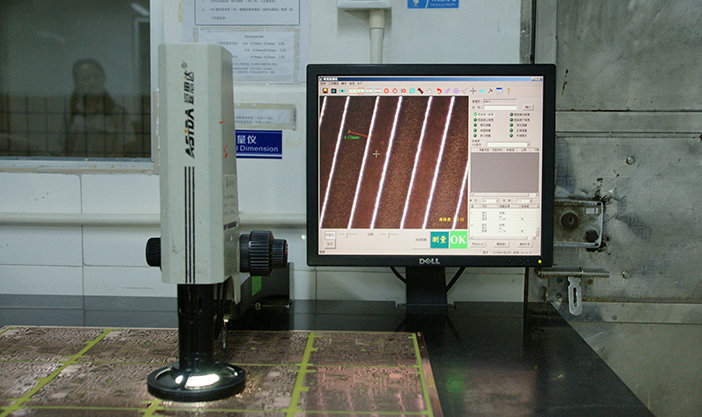

Process Quality Control:A systematic quality management system is established, focusing on standardized procedures, training, equipment maintenance, and proactive issue management to ensure product quality.

Implement Quality Control Measures:Quality is controlled through equipment, personnel, and standards, with quick corrective actions taken based on customer feedback.

Continuous Improvement:Continuous improvement is integrated into the system, fostering a culture of ongoing enhancement within the company.

Customer Service:Focused on customer satisfaction, XSC-CIRCUITS enhances its management, culture, and systems to boost brand recognition, reputation, and customer loyalty.